Cooling Tower Cycles of Concentration (COC) are limited by the nature of the impurities they concentrate during An open recirculating cooling system uses the same water repeatedly to cool process equipment. Low cycles of concentration (high amount of blowdown in Aquatech’s Cooling Tower Blowdown Recovery Process can return nearly all of the blowdown volume for use as service or demineralized water. Cycles of concentration is an industry term used to describe the relationship between the amount of system feed water flow and the amount of flow sent down the drain as blowdown. Monitoring and Control of Cooling Water EquipmentEach of the treatment concerns can decrease cooling tower performance, increase the use of water treatment chemicals as well as reduce cycles of concentration. Rate & Delta T & Evap Factor Dec 2012 Newsletter) 3 gpm per 100 Tons or 480 GPM Evaporation Cycles of Concentration (COC) 4 Cycles Actual 4 Cycles Desired (1) 4 Cycles Makeup Rate Evaporation + Blowdown 480 GPM + ( Evap Rate/ (COC Understanding the Inputs: Cooling Tower Volume per area (gal/ft/yr): The amount of water being recirculated.The Nation Average for Buildings with cooling towers use 7 gallons of water more (per sf annually) than those without and is thus setup as an automated input which a user can modify. Cooling Tower Mathematics Acid Feed Requirements What you need to Know Example System Result Evaporation Rate 16000 Ton Chiller Plant (or use Recirc.

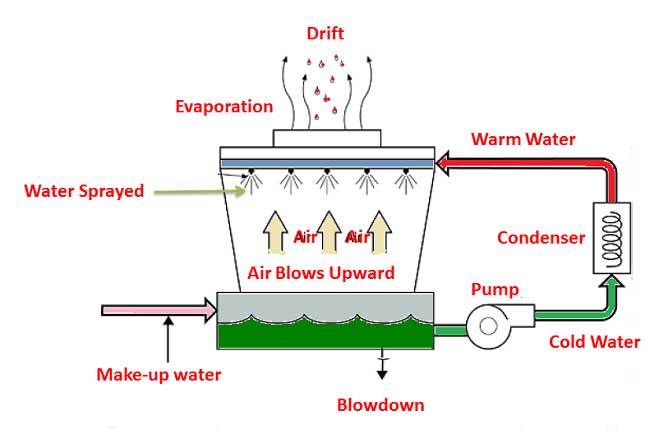

However, open recirculating cooling systems are inherently subject to more treatment-related problems than once-through systems: The quantity of water discharged to waste is greatly reduced in the open recirculating method, and chemical treatment is more economical. System thermal load (evaporation rate), the bleed rate employed.Open recirculating cooling systems save a tremendous amount of fresh water compared to the alternative method, once-through cooling. This ratio can be optimized by controlling the cooling tower WARNING: Check to ensure the controls for the fan motor are set to allow a maximum of. Moreover, the cycles of concentration is a ratio of the concentration in suspended solids between the blowdown water and the make-up water. Cooling towers, spray ponds, and evaporative condensers are used for this purpose.The mass balance of a cooling tower system can be written as the following: This equation doesn’t take account of the process leaks, the windage and drift which are just forms of uncontrolled blowdown.

airborne gases such as sulfur dioxide, ammonia or hydrogen sulfide can be absorbed from the air, causing higher corrosion rates the longer retention time and warmer water in an open recirculating system increase the tendency for biological growth the relatively higher temperatures significantly increase corrosion potential

Sometimes called "hyperbolic" towers due to the distinctive shape and function of their chimneys, natural draft towers do not require fans. Mechanical draft towers are further subdivided into forced or induced draft towers.Natural draft towers. Some sensible heat loss (direct cooling of the water by the air) also occurs, but it is only a minor portion of the total heat rejection.Cooling towers are classified by the type of draft (natural or mechanical) and the direction of airflow (crossflow or counterflow). Heat rejection is primarily by evaporation of part of the cooling water. They are designed to provide intimate air/water contact.

In a forced draft design, fans push air into the bottom of the tower. Mechanical draft towers use fans to move air through the tower. In both models, the empty chimney accounts for most of the tower height.Mechanical Draft Towers. In a counterflow model, the fill is inside the shell. The fill is external to the shell forming a ring around the base.

In counterflow towers, air moves upward, directly opposed to the downward flow of water. These towers can use either crossflow or counterflow air currents and tend to be larger than forced draft towers.Counterflow Towers. Induced draft towers have a fan at the top to draw air through the tower.

Often, the deck is covered to retard algae growth.Fill Section. Crossflow towers usually have a gravity feed system-a distribution deck with evenly spaced metering orifices to distribute the water. The crossflow design provides an easier path for the air, thus increasing the airflow for a given fan horsepower. In crossflow towers, air flows horizontally across the downward flow of water. Headers and spray nozzles are usually used to distribute the water in counterflow towers.Crossflow Towers.

Other types of fill include plastic splash grid, ceramic brick, and film fill.Film fill has became very popular in recent years. Splash bars are now available in plastic as well. Originally, fill consisted of "splash bars" made of redwood or pressure-treated fir. Packing or fill of various types is used to keep the water distributed evenly and to increase the water surface area for more efficient evaporation.

Because of the very close spacing, film fill is very susceptible to various types of deposition. Splash fill can be partially or totally replaced with film fill to in-crease the capacity of an existing cooling tower. Chlorinated PVC (CPVC) can withstand temperatures to approximately 165☏.Film fill provides more cooling capacity in a given space than splash fill. Polyvinyl chloride (PVC) is commonly used for systems with a maximum water temperature of 130☏ or less. Film fill is typically made of plastic.

Drift should be minimized because it wastes water and can cause staining on buildings and autos at some distance from the tower. Because drift has the same composition as the circulating water, it should not be confused with evaporation. "Drift" is a term used to describe droplets of water entrained in the air leaving the top of the tower. Louvers are used to help direct airflow into the tower and minimize the amount of windage loss (water being splashed or blown out the sides of the tower).Drift Eliminators. Any type of deposition can severely reduce the cooling efficiency of the tower.Louvers. Process contaminants, such as oil and grease, can be direct foulants and/or lead to heavy biological growth on the fill.

It is not practical to design a tower to cool to the wet bulb temperature. The "wet bulb temperature" is the lowest temperature to which water can be cooled by evaporation. They are more effective in removing drift than the early wood versions, yet cause less pressure drop.Cooling towers are designed to cool water to a certain temperature under a given set of condi-tions. Modern drift eliminators are typically made of plastic and come in many different shapes. Early drift eliminators were made of redwood in a herringbone structure.

For simplicity, this is often assumed to be the case. The following equation describes this relationship between evaporation, recirculation rate, and temperature change:Where: E = evaporation, gpm RR = recirculation rate, gpmDT = cooling range, ☏ F = evaporation factorThe evaporation factor, F, equals 1 when all cooling comes from evaporation. This is equal to evaporation of about 1% of the cooling water for each 10☏ temperature drop across the cooling tower. For calculation purposes, blowdown is defined as all nonevaporative water losses (windage, drift, leaks, and intentional blowdown).Makeup is added to the system to replace evaporation and blowdown.Approximately 1000 Btu of heat is lost from the water for every pound of water evaporated. Cooling range is usually around 10-25☏ but can be as high as 40☏ in some systems.Water circulates through the process exchangers and over the cooling tower at a rate referred to as the "recirculation rate." Water is lost from the system through evaporation and blowdown. The temperature difference between the hot return water and the cold sump water is referred to as the "cooling range" (DT ).

At 3 cycles of concentration, blowdown has three times the solids concentration of the makeup. "Cycles of concentration" (or "cycles") are a comparison of the dissolved solids level of the blowdown with the makeup water. Note that blowdown has the same chemical composition as circulating water. The actual F value for a system is generally between 0.75 and 1.0, but can be as low as 0.6 in very cold weather.As pure water is evaporated, minerals are left behind in the circulating water, making it more concentrated than the makeup water.

0 kommentar(er)

0 kommentar(er)